Posts by pwsadmin

Deep brining systems

Deep brining systems are designed to brine many cheeses at the same time. The cheeses are stacked in stainless steel racks and lay on special industrial fabrics to protect the surface of the cheeses. The racks are placed on a cart. A hoist that moves over 1 or 2 beams picks up the rack with…

Read MoreBrine tubs

The brine tub is made of a high quality stainless steel (AISI 3.16) A cooling pipe is a standard built-in feature to cool down the brine. The brine tub is placed on legs. Dimensions depend upon the size of cheesemaking operation. The brine tub is delivered with a plastic surface protection for transport.

Read MoreCurd bags

Curd bags are used for the drainage of curd or yogurt (Greek yogurt). We offer 2 sizes of curd bags:1. Small curd bag Gross content 8 kg / 17 lbs Net content 2.5 kg / 5.5 lbs Dimensions 48 x 32 cm / 19″ x 12.5″ 2. Large curd bag Gross content 50 kg /…

Read MoreDrainage table

Drainage tables are custom made to fit the type of cheese making operation. Simple drainage table on wheels Drainage table with multi molds Filling of the multi molds

Read MoreAutomatic drainage-finishing table

The automatic drainage-finishing table is used to pre-press the curd and drain the whey and cut blocks that fit into a particular size of cheese mold. The machine is PLC controlled and has a color touch-screen from where the parameters can be entered for different sizes and styles of cheese. An overhead device moves over…

Read MoreManual drainage-finishing table

A drainage-finishing table can be used to pre-press the curd and drain the whey and cut blocks that fit into a particular size of cheese mold. The manual drainage-finishing table is made to fit to the capacity of curd in the cheese vat. The curd can flow by gravity from the the cheese vat to the drainage-finishing…

Read MoreTube cheese press

Capacity 2-6 stamps The tube cheese press is designed to press small quantities of the same size of molds in a stack (1 lbs – 8.8 lbs) The cheese press is determined by the number of pressing stamps and the size of the molds to be pressed. The pressure can be adjusted by changing the position…

Read MoreHorizontal cheese press

Capacity 2-6 cylinders The horizontal cheese press is very easy to operate and every mold is equally pressed. The capacity of the cheese press is determined by the number of cylinders and the size of molds to be pressed. A stack can be made for different sizes of cheese. The press is delivered on adjustable…

Read MoreA-frame cheese press

Capacity 2-20 cylinders The A-frame cheese press is very easy to operate and is used whenr>more molds of the same size are pressed. The capacity of the cheese press is determined by the number of cylinders and the size of molds to be pressed. A stack can be made for different sizes of molds by…

Read MoreMechanical cheese press

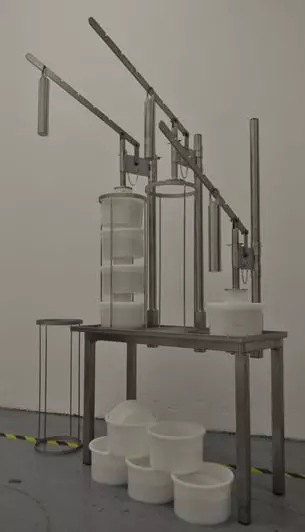

Capacity 2-6 stamps The mechanical cheese press is a less expensive alternative for the pneumatic cheese press. The capacity of the cheese press is determined by the number of pressing stamps and the size of molds to be pressed. The pressure can be adjusted by stainless steel weights through a system of level arms and cords.…

Read More